Market Overview

According to latest research conducted, the global market of Polyacrylate Rubber is anticipated to grow with a CAGR of 7% to 8% in between the assessment period of 2021-2031.

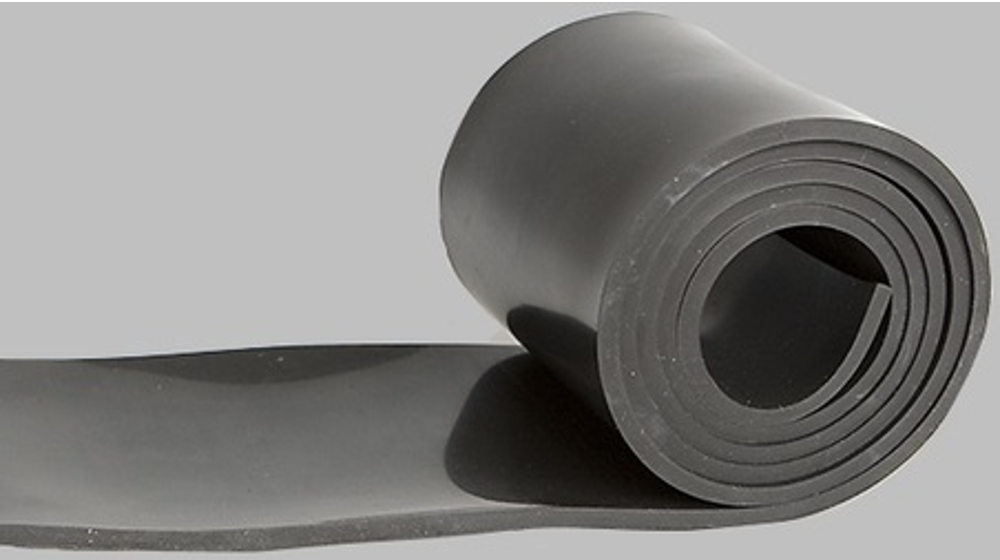

Polyacrylate Rubber, also otherwise known as Acrylic Rubbers (ACM), are unsaturated polar rubbers that have a strong resistance to oxygen, ozone, and high temperatures, as well as an excellent swelling resistance in mineral oils. However the material also exhibits a high water absorption rate and poor hydrolysis resistance.

Polyacrylate Rubber is in higher demand than ever before, thanks to rising automobile manufacturing and the necessity for long-lasting & high performance components. The demand for this material is projected to grow significantly due to the rising demand for reduced fuel consumption and increased combustion temperature in the engine compartment.

Request a report sample to obtain authentic analysis and comprehensive market insights at @ https://www.futuremarketinsights.com/reports/sample/rep-gb-13674

What is Driving Demand for Polyacrylate Rubber?

Rubber consumption has increased as a result of industrialization in a variety of sectors for diverse uses. Rubber consumption is skyrocketing as the world’s urban population grows. The majority of artificial rubber is utilized in the automobile industry. Usage in electronic equipment and for components in numerous equipment & industries is also on the increase.

In the same way, Polyacrylate Rubber is also becoming more popular in a variety of applications, including coatings, textiles, seals & gaskets, adhesives, plastics, motor oils and lubricants, pipelines, and others. Among them, Ethyl acrylate rubbers are increasingly preferred over other types of this rubber due to their better qualities, such as strong heat, oxygen, and ozone resistance.

Some of the other reasons boosting demand for Polyacrylate Rubber in the global market include increased automobile production and a growing preference for components with good performance in extreme working conditions.

Furthermore, increased demand from end-use sectors such as consumer products and plastics is likely to propel the market forward.

Request Complete TOC Of this Report @ https://www.futuremarketinsights.com/toc/rep-gb-13674

Polyacrylate Rubber Witnessing High Demand from the Automotive Industry

The global Polyacrylate Rubber market is primarily driven by the rising automotive industry and increasing vehicle demand due to the changing lifestyle. This acrylic rubber is primarily utilized in the automobile industry to lend strength to seals and packaging. The growing need for oil-resistant materials has also led to the introduction of these rubbers in vehicle seals.

Furthermore, the desire for low-fuel consumption is increasing, and the growing temperature in the engine compartment helps to increase the demand of the rubber in the automotive industry owing to its excellent high temperature operational performance. This rubber formulation is also used in vibration damping mounts because of its damping qualities.

US and Canada Polyacrylate Rubber Market Outlook

The North America region (US and Canada) is estimated to be one of the major markets for Polyacrylate Rubber owing to the higher demand of the material from sealing and packaging applications in a variety of end-use industries.

Owing to its numerous applications in textiles, adhesives, and coatings, market for Polyacrylate Rubber is projected to offer significant opportunities in the US due to the high growth of industries such as automotive, textiles and paints and coatings.

Ask an Analyst @ https://www.futuremarketinsights.com/askus/rep-gb-13674

APAC Demand Outlook for Polyacrylate Rubber

Increased purchases of heavy-duty trucks and commercial vehicles in the APAC region have been boosted by factors such as economic expansion and ongoing high levels of infrastructure expenditures. As a result, the market in the Asia Pacific area has benefited from the strong demand from automotive component manufacturers.

Because of the region’s thriving automotive sector, Asia Pacific, particularly China, is also likely to contribute considerably to the total market. Other key markets for this rubber in the region include Japan, South Korea, India and the ASEAN countries.

Who are the Key Manufacturers and Suppliers of Polyacrylate Rubber?

Some of the leading manufacturers and suppliers include

- Hi-Tech Polymers

- Ames Rubber Manufacturing

- DuPont

- Elder Rubber Company

- GBSA

- CANADA SILICONE INC.

- Kivi Markings

- Specialty Tapes Manufacturing

- REDCO

- Jiujianshilong

- Plexipave

- Sreeji Trading Company

- Harboro Rubber

- Rubber Mill

- Qinglong

- Apcotex Industries Ltd.

- Anabond Limited

- Tiger Rubber Company

- ZORGE

- Hanna Rubber Company

- Synthos SA

- Vanderbit Chemicals LLC

- Devcon

- Fostek Corporation

- INEOS Nitriles Company

- PAR Group

- Jet Rubber Company

- NOK

- ZEON

- Haiba

- Continental AG

- Zhongce Rubber Group

- Cheng Shin Rubber Industry Co.

- Unimatec Chemicals.

To achieve technical advancements in the product formulation, market players are employing a variety of strategies and investing heavily in R&D. However, the rubber market is now being impacted by the COVID-19 epidemic, which has caused most industrial operations to be temporarily halted.

As a result, demand and the supply chain have been impacted, limiting growth in the year 2020. However recovery in the automotive sector starting in the first half of 2021 is expected to provide steady opportunities for the key players.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain. The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

Market Report Highlights:

- Detailed overview of parent market

- Changing market dynamics in the industry

- In-depth market segmentation

- Historical, current and projected market size in terms of volume and value

- Recent industry trends and developments

- Competitive landscape

- Strategies of key players and products offered

- Potential and niche segments, geographical regions exhibiting promising growth

- A neutral perspective on market performance

- Must-have information for market players to sustain and enhance their market footprint

Note: Although care has been taken to maintain the highest levels of accuracy in FMI’s reports, recent market/vendor-specific changes may take time to reflect in the analysis.

Key Segments

By Source:

- Ethyl Acrylate (EA)

- Butyl Acrylate (BA)

- Methoxyethyl Acrylate (MEA)

- Ethoxy Ethyl Acrylate (EEA).

By Application:

- Gaskets

- O-rings

- Beltings

- Adhesives

- Shaft seals

- Plastics

- Engine Oils and Lubricants

- Piping

By End Use Industries:

- Packaging

- Automotive

- Consumer Goods

- Chemicals & Materials

By Region:

- North America (U.S., Canada)

- Europe (Germany, Italy, France, U.K., Spain, BENELUX, Russia, Nordics)

- East Asia (China, Japan, South Korea)

- South Asia and Pacific (India, ASEAN Countries, Oceania)

- Latin America (Brazil, Mexico)

- Middle East and Africa (GCC Countries, Turkey, Northern Africa, South Africa)