Cost-effectiveness, durability, and lightweight are several advantages responsible for boosting the demand for multilayer flexible packaging, worldwide. The scope of this market study includes multiple flexible packaging solutions such as bags, pouches & sachets, wrapping films, laminates, and others (liners, stick packs, and more). Manufacturing of multilayer flexible packaging products requires 70% less material when compared to rigid packaging products. Aluminum foil and metalized plastic films are also gaining significant traction for the manufacturing of bags and pouches for flexible packaging.

The global multilayer flexible packaging market is set to progress at a CAGR of around 4% over the period of forecast, and reach a valuation of nearly US$ 350 Bn by 2029.

“Shift from rigid packaging to flexible packaging is the leading trend in the global packaging industry. Changing packaging needs enable brand owners to enjoy high profitability margins, owing to reduction in transportation cost and cheaper package cost.”

To Get Sample Copy of Report visit @ https://www.futuremarketinsights.com/reports/sample/rep-gb-9718

Key Takeaways of Multilayer Flexible Packaging Market Study

- In terms of value, the pouches & sachets segment is expected to account for maximum market share in the global multilayer flexible packaging market during 2019-2029, attributable to the rising demand for small-sized sachets & pouches for the packaging of a variety of food products.

- By layer structure, the 5 layer segment is anticipated to grow 1.2X by the end of 2023.

- The plastic material segment is expected to create total incremental revenue opportunity of US$ 96 Bn by the end of 2029, owing to ease of availability and cost-effectiveness.

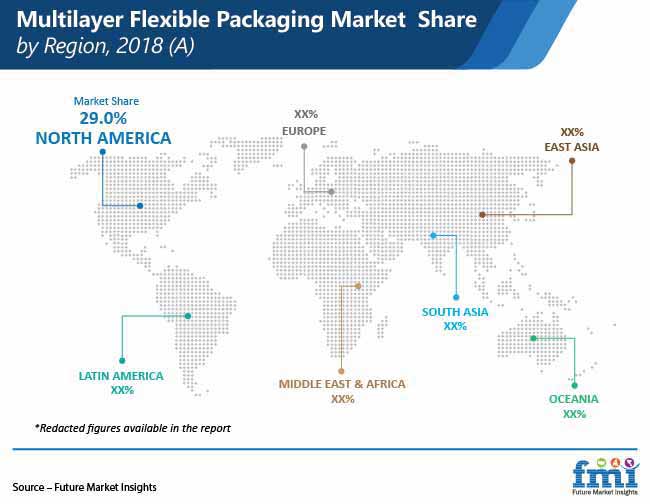

- North America is anticipated to maintain its dominance in the global multilayer flexible packaging market during the forecast period. This growth can be attributed to the presence of well-established market players in the region. East Asia and South Asia are anticipated to be highly lucrative markets, on the back of significant consumption and production of multilayer flexible packaging solutions at cost-effective rates.

Multilayer Flexible Packaging Market Landscape

The global multilayer flexible packaging market is identified as a highly competitive and fragmented market. Unorganized and local players can leverage significant growth opportunities in the global multilayer flexible packaging market. Some of the key players operating in the multilayer flexible packaging market are Sealed Air Corp., Mondi Group Plc, Berry Global Group, Inc., Scientex Berhad, and Uflex Ltd., among others. Key players are focusing on acquisitions and product innovation with the aim of expanding their footprint and customer base across the globe.

- In November 2019, Constantia developed its first plant Constantia Ecoflex at Ahmedabad, India, for producing sustainable and recyclable flexible packaging.

- In February 2019, Amcor Limited introduced Genesis, a polyethylene laminate with the look and feel of traditionally-oriented polyethylene or oriented polyester. This product is suitable for use in medical, food, homecare, personal care, and other industries. The company acquired Bemis Company Inc., which is one of the leading manufacturers of multilayer flexible packaging.

- In June 2019, Sealed Air Corp. acquired MGM’s flexible packaging business. MGM is a privately-held company that is headquartered in Manila, the Philippines. This acquisition will allow the company to expand its food packaging operations in Asia.

Download Methodology of this Report @ https://www.futuremarketinsights.com/askus/rep-gb-9718

About Multilayer Flexible Packaging Market Report

Future Market Insights, in its new report, offers an unbiased analysis of the global multilayer flexible packaging market, analyzing historical demand of 2014-2018 and forecast statistics for 2019-2029. The study offers growth projections on the multilayer flexible packaging market based on product (bags, pouches & sachets, wrapping films, laminates, and others [liners, stick packs, etc.], material (plastic [ polyethylene terephthalate (PET), polypropylene (PP) (BOPP, OPP, and CPP), polyethylene (PE) (LDPE, LLDPE, and HDPE), ethylene vinyl alcohol (EVOH), polyamide, polyvinyl chloride (PVC), ethylene vinyl acetate (EVA), polyvinylidene chloride (PVDC)]), layer structure (3 layers, 5 layers, 7 layers, and above 7 layers), and end-use industry (food, beverages, pharmaceuticals, automotive, cosmetics and personal care, homecare, electrical & electronics, agriculture & allied industries, and textiles & apparels), across seven key regions.