Future Market Insights (FMI) has forecasted that the global aluminum foam market will record healthy growth between 2020 and 2030, progressing at a steady CAGR of 4.5%. Furthermore, the study projects that the global value of the market will cross US$ 35 Mn by 2030.

The report attributes the growth of the market to persistent demand across automotive and construction industries, owing to the material’s superior electrical, mechanical, and structural characteristics.

Similarly, the study has identified increasing inclination towards sustainable raw materials and the growing trend of lightweight vehicles will bestow remunerative opportunities to market players.

The analysts at FMI also remark that an increasing stringency of regulations restricting the usage of plastic polymer foams is asserting end-users to seek sustainable alternatives such as aluminum foam.

However, the report opines that the COVID-19 pandemic poses a major challenge to the growth of the market owing to hampered operations in the automotive and construction industries, which are the major revenue drivers for the aluminum foam market.

Key Takeaways

- Open cell foam will remain the most sought variant, capturing more than 70% of market value, backed by high strength over its counterpart, closed cell foam.

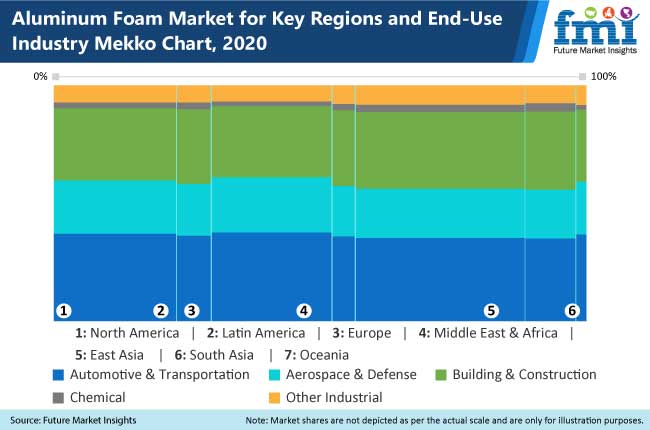

- The automotive and transportation sector is the most lucrative end-use segment, accounting for over 1/3rd of market value.

- Aluminum foam’s application as an energy absorber, heat exchanger, and damping structure cumulatively account for 2/3rd of the market value.

- East Asia will remain the largest region for aluminum foam, capturing over 1/3rd of value, owing to the presence of a thriving automotive industry.

- Europe and North America will collectively capture nearly 2/5th of value, backed by high demand in aircraft and automobile production.

“Market players are focusing on adopting advanced technologies to ensure the production of superior quality aluminum foams with high strength,” remarks FMI analyst.

COVID-19 Impact

The outbreak of COVID-19 has brought operations in the automotive, aviation, and construction sectors to a screeching halt, thus leading to a downtrend in the demand for several raw materials, including aluminum foam. Moreover, the demand contraction can be attributed to decreased spending on non-essential goods and cost cuttings by end-users.

Furthermore, supply-side challenges such as unavailability of raw materials and supply chain disruptions on the back of government-imposed travel restrictions are hindering the production of aluminum foams. On these lines, the growth trajectory of the aluminum foam market will behold fluctuations during the pandemic and the revamp appears to be slow and delayed.

Who is Winning?

Manufacturers of aluminum foam are enhancing their production technologies to improve the quality of end-products. Likewise, entering strategic partnerships has also been identified as a key growth strategy adopted by market players. On these lines,

- Beihai Composite Materials Co. produces aluminum foams specifically designed for sound reduction purposes.

- In December 2017, Cymat Technologies Ltd. entered a partnership with Spain-based Alucoil SA to produce aluminum composite panels with metallurgically-bonded aluminum foam cores.

FMI’s report includes profiles of some of the most prominent names in the market including Beihai Composite Materials Co., Ltd., Composite Materials Ltd., Cymat Technologies Ltd., American Elements Corporation, ERG Aerospace Corp., Hollomet GmbH, Pohltec Metalfoam GmbH, VIM Technology Ltd, Nanoshel LLC, Aluinvent Ltd., and Havel metal foam GmbH, among others.

For More Details, Ask Analyst @ https://www.futuremarketinsights.com/ask-question/rep-gb-8402

Key Segments

Product Type:

- Open Cell Foam

- Closed Cell Foam

- Others

Application Type:

- Energy Absorber

- Heat Exchanger

- Damping Structures

- Filtration

- Insulation

- Others

End-use Industry:

- Automotive & Transportation

- Aerospace & Defense

- Building & Construction

- Chemical

- Other Industrial

Regions:

- North America

- Latin America

- Europe

- MEA

- East Asia

- South Asia

- Oceania