According to the latest magnesium metal market report published by Future Market Insights, the long-term outlook of the global magnesium metal market remains optimistic. Global magnesium metal revenues are set to grow at a CAGR of over 7% through 2031. The market for magnesium metal witnessed a massive slowdown in its progress as a result of the spread of the Covid-19 pandemic across the globe. The level of demand declined to the extreme level due to lockdown creating hurdles for the key players operating in this market. However as recovery commences in 2021, major players are recuperating their positions through production expansion, capacity utilization, and online selling in 2021 keeping in view the covid-19 norms.

Request For Sample of This Report Copy in PDF: https://www.futuremarketinsights.com/reports/sample/rep-gb-1550

Analysis of the Magnesium Metal Market

The use of magnesium metal and magnesium metal alloys in aircraft and aerospace applications is expected to witness steady growth over the forecast period. Over the years, aircraft manufacturers across the globe have focussed on developing lighter and more fuel-efficient aircraft in order to adhere to stringent emission norms and regulations imposed by various regulatory bodies and associations. Magnesium metal is one of the lightest metals on Earth.

Moreover, magnesium metal is relatively more dimensionally stable, resistant to elevated temperatures, and relatively easier to process. Also, the reduction process associated with the manufacture of metals such as titanium, hafnium, uranium, zirconium, and beryllium, among others, is one of the major application areas for magnesium metal.

Titanium is obtained from ores such as

- Rutile,

- Ilmenite,

- leucoxene, and

- Pervoskite, among others.

Major steps involved in the production process of magnesium metal include extraction, purification, and sponge production.

Magnesium Metal Market: Factors Impacting Growth

The global magnesium metal market report has been analysed on the basis of application. By application, magnesium metal is used in die-casting, aluminium alloys, metal reduction, desulphurization, and others.

The global magnesium metal market has been viewed as a high value, moderate growth type market, which is expected to follow suit during the forecast period. During the past decade, the world has witnessed a rising preference for magnesium metal, which is primarily due to its application in aluminium alloy.

Request a Complete TOC of this Report with figures: https://www.futuremarketinsights.com/toc/rep-gb-1550

The main reason for the growth of the magnesium metal market is its increased adoption rate. Increasing emphasis on automotive light-weighting is also expected to impact the magnesium metal market positively over the forecast period. Growing automotive sales and a corresponding increase in automotive /vehicle parks is expected to result in a significant increase in environmental greenhouse gas emissions.

Magnesium metal is around 65% lighter than steel and 33% lighter than aluminium. Moreover, the use of magnesium metal for automotive components results in parts that are not only lighter in weight but also relatively more dimensionally stable. Besides, several intricate and thin-walled components can be manufactured with relatively more ease vis-à-vis some of the conventional materials.

Magnesium Metal Market: Segmentation

Application

- Die-casting

- Aluminium Alloys

- Metal Reduction

- Desulphurization

- Others

Region

- North America

- Latin America

- Western Europe

- Eastern Europe

- Asia Pacific Excl. Japan

- Middle East and Africa

- Japan

Magnesium Metal Market: Top Participants

Some of the market participants identified in the magnesium metal market are

- US Magnesium LLC.,

- Dead Sea Magnesium Ltd,

- POSCO, RIMA Group,

- Solikamsk Magnesium Works OAO,

- Wenxi YinGuang Magnesium Industry (Group) Co., Ltd.,

- Shanxi Wenxi Hongfu Magnesium Co., Ltd.,

- Shanxi Wenxi Zhenxin Magnesium Co., Ltd., and

- Taiyuan Tongxiang Magnesium Co., Ltd.

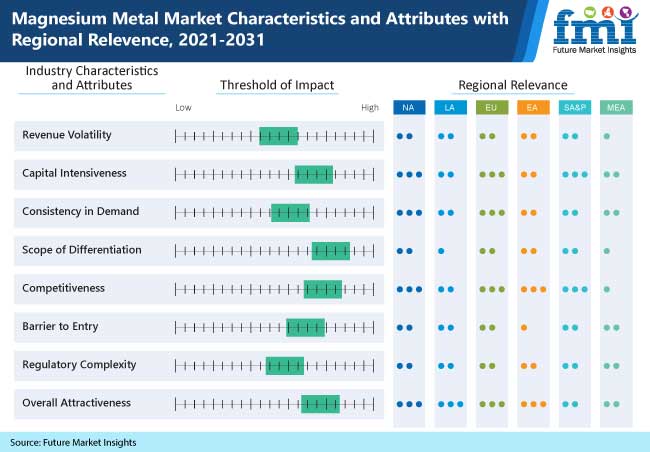

The magnesium metal market is a highly competitive market, consisting of tier-1 global scale manufacturers and a greater proportion of small-scale magnesium metal manufacturers catering to domestic demand. However, large industrial operations seek products from reputed magnesium metal manufacturers for demand procurement.

Key strategies employed by tier-1 magnesium metal manufacturers include the provision of effective sales and services, strategic tie-ups with regional distributors/manufacturers to foray into expansion in untapped markets, and undergoing restructuring business operations to optimize the use of resources.